The C-frame benchmark for highest rigidity

Order quickly and easily Spare Parts, Service Products and Training courses. Place your orders around the clock with by using our DMG MORI online shop. Here you will find original spare parts, training courses and accessories with prices, product descriptions and technical specifications conveniently, at a glance. DMG MORI supports customers in all phases - from greenfield consulting, process development to consulting on regulatory issues, e.g. ISO13485 or FDA. Whereby the technological possibilities are not in fact the limiting factor here, instead it is the high demands on the certification requirements and standardisation that determine the process in.

- DMG MORI offers a unique range of machine tools of several sizes. Browse DMG MORI used machines – one of the largest manufacturers of metal cutting machines. Head Office 2-35-16 Meieki, Nakamura-ku, Nagoya City, Aichi 450-0002, Japan Tel 81-(0)52-587-1811 Fax 81-(0)52-587-1818 E-Mail:Parts Center in Japan E-Mail:Dallas Parts Center E-Mail.

- Home / Products / DMG Mori. Showing 1–100 of 259 results Machine Brand None DMG Mori 259.

- Improved C-frame concept with movable table as X-axis

- Rigid Y-axis concept in whole range of travel

- FEM-optimized design & construction

Precision in every component and detail

- Accuracy of positioning in all axes of 0.00023 in without linear scales (according to ISO 230-2)

- Ball-screws made in first class of tolerances (IT 1)

Sophisticated design, small footprint and large working area - combined in the CMX V series

Dmg Mori Seiki Parts

- Improved ergonomics for easy handling and loading of heavy workpieces

- Huge table with 55.1 x 22.0 in for machining of parts up to 2,204.6 lb

- Small foot print 93.6 ft2

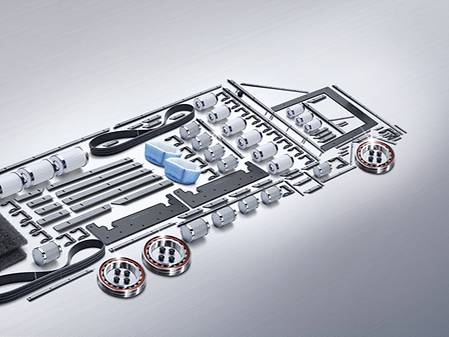

On board: More than 20 precision parts made on DMG MORI machines

'>Dmg Mori Seiki Spare Parts

Sailing to the limits of physics

People and materials are pushed to the limit during a regatta like the Vendée Globe. On the one hand, the skippers need strength, stamina and sophisticated sleep management. On top of that, they have to be technically skilled to be able to repair important parts of the yacht themselves in wind and storm. On the other hand, the yachts are constantly exposed to incredible forces – wind, waves and extreme loads are unforgiving when it comes to tearing the material – often with tonnes of force. It is not uncommon for the yachts to move in a way that pushes the limits of physics.

With combined expertise to create a high-end yacht

It’s all the more important to have a strong, reliable boat that can defy these forces. Three central skills came together when building the “DMG MORI Global One”: experience from professional sailors, knowledge from passionate boat builders and expertise from a world-leading machine tool manufacturer.

Dmg Mori Parts Email

Multiplast, a French boat builder in the field of high-end yachts, built the IMOCA 60, while the DMG MORI Sailing Team supported the project with all of its experience and expertise. At the same time, DMG MORI produced critical parts and complex components – DMG MORI machines produced over 20 high-precision components which were used in the construction of the IMOCA 60.